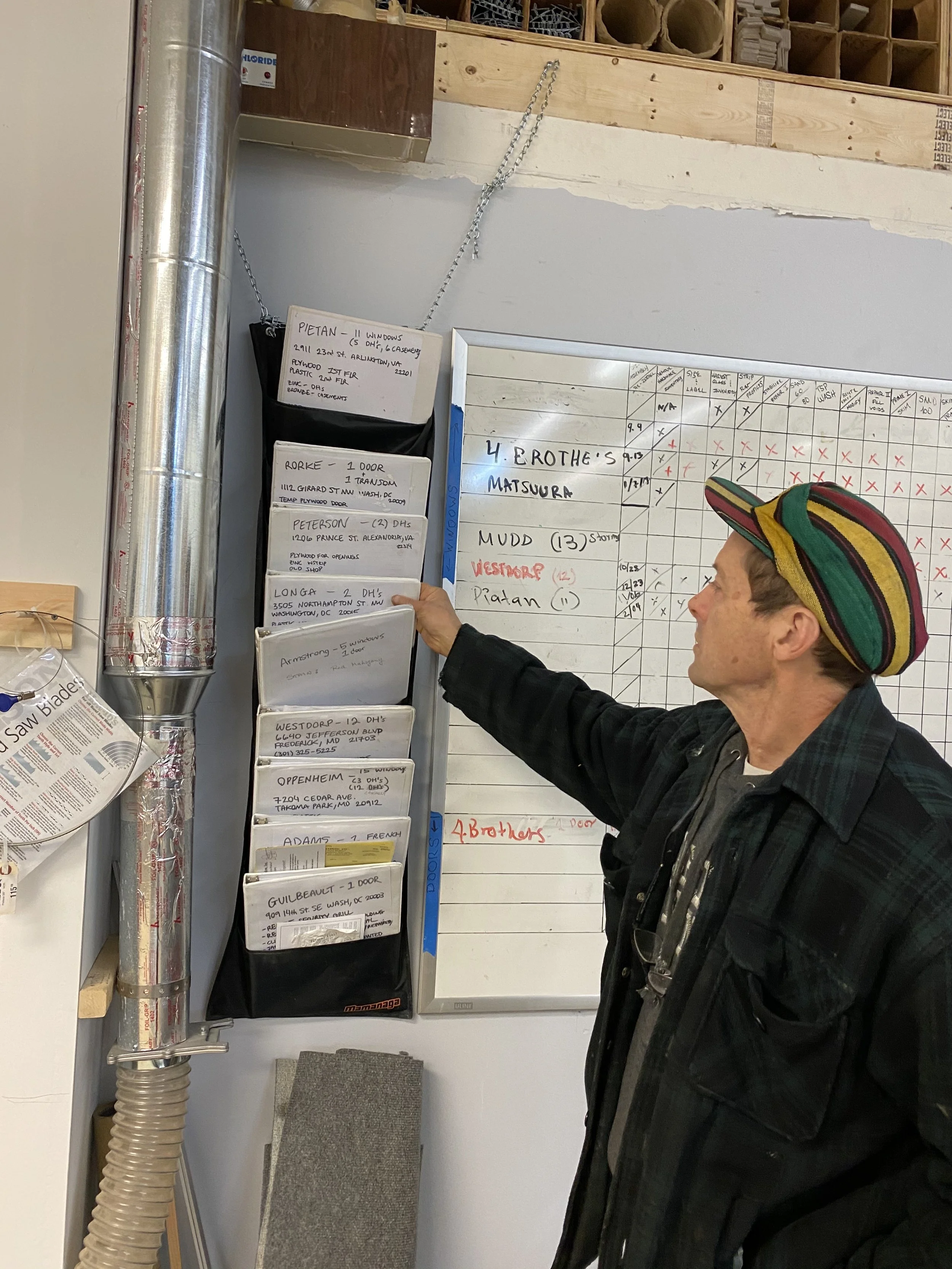

How It’s Done

Every Mozer project starts with meticulous information gathering and planning to ensure the beautiful and lasting results you expect

The great joy for me is the beauty of seeing something old come alive again and work as it should. You don’t see a lot of that today.

David Rogers

-

De-Leading

This process starts at your project site, where we apply utmost care in determining the presence of lead paint and, when found, protecting you and your belongings as windows/doors are removed for off-site restoration. Our shop features a dedicated lead paint removal room designed to capture and dispose of this harmful substance in a way that’s safe for not only our workers, but for the environment as well.

-

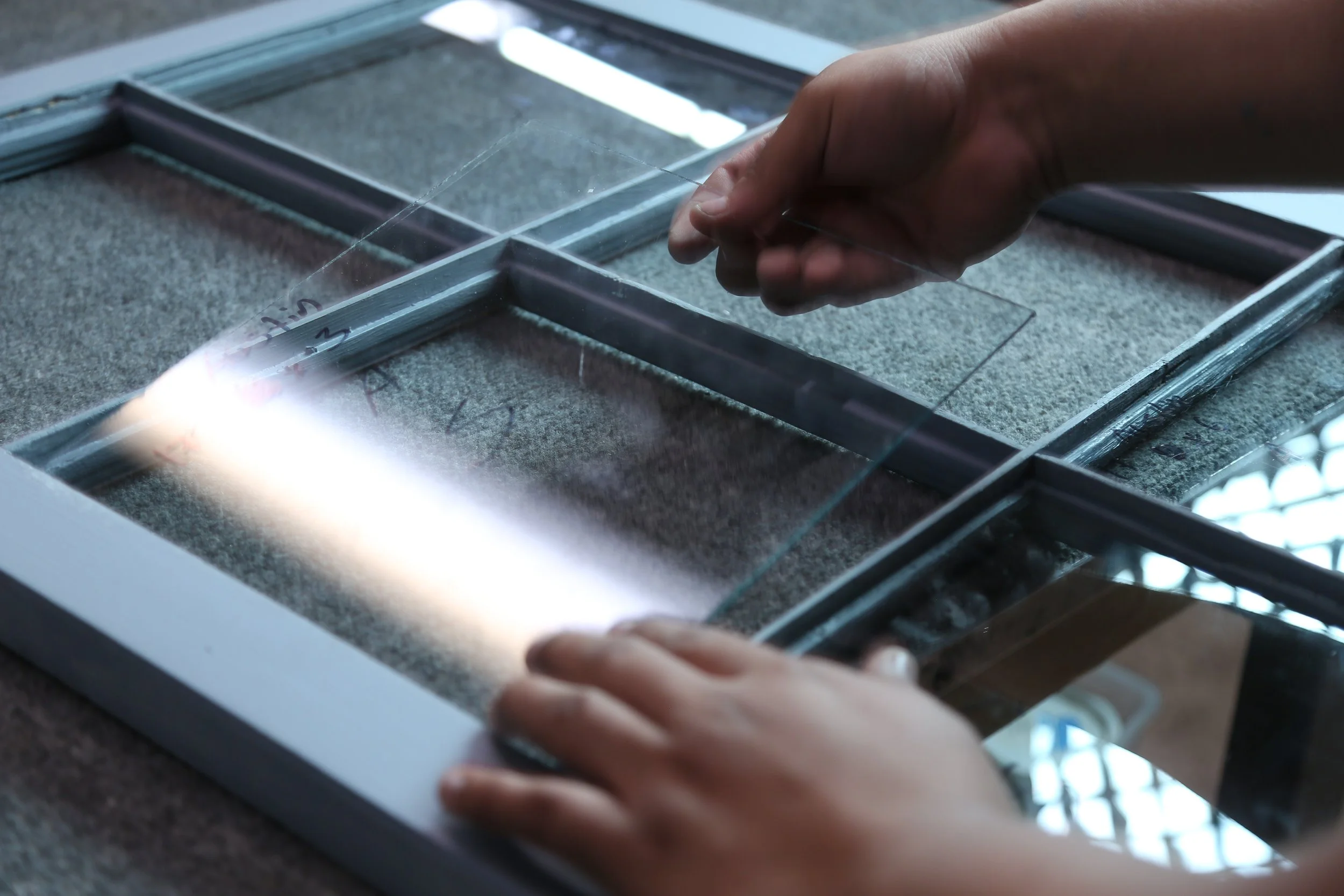

Reglazing

Window glazing is a putty-like substance used to secure the glass in the sash and provide a protective seal against the outside elements. When this key part of the window is damaged or just past its prime, we completely remove and replace it. In our expert hands, the finished glazing not only serves its function well, it visually disappears into the window’s overall design.

-

Glass Replacement

With a diverse inventory of recovered historic glass at our disposal, we’re typically able to replace damaged panes with authentic replacements. While modern glass has its advantages, artisan glass—particularly that made in the early 20th century and before—has an aesthetic character that’s truly unique. We handle all shapes and sizes, and are well-versed in reviving specialty systems like leaded and stained glass.

-

Weatherization

A key component to limiting air movement through your windows and doors is weather stripping. The modern rubber/plastic-like materials used for this task are finicky and prone to breaking down over time. We avoid these types of materials in favor of shop-made classic zinc or bronze interlocking weather stripping. This provides durable protection and a distinctive, yet subtle visual effect.

-

Hardware Rehab

Whenever possible, we retain your windows’ and doors’ original locks, pulls, and pulley & weights and return them to near-new operating condition. And if some of your hardware is beyond repair, we turn to our in-house inventory of refurbished recovered pieces or approved replica replacements when necessary.

-

Wood Repair

Similar to the glass and hardware elements, we preserve all wood parts that are viable. Small to medium repairs are made with fillers or special epoxies, while larger repairs (sometimes whole sections of the original) are made by fashioning new parts from old-growth wood we’ve sourced. We never use inferior quick-growth wood typically found at big-box stores and some lumber yards.

-

Finishing

This final touch to the process brings your windows to life and ensures unmatched ease of operation. We apply only the highest quality primers, paints, and stains, and always lightly sand between coats to increase adhesion and longevity. What really sets us apart is our friction-free technique: We apply a linseed oil-only finish to edges where the most friction occurs, making opening and closing a breeze.

Restoration Walk-Through

In this video, owner Neil Mozer narrates the major stages of the restoration process.

Ready to get an estimate? Fill out our Start Your Project form.